For The Love of Making Chocolate: Micelli Interviews Ritual Chocolate

For The Love of Making Chocolate: Micelli Interviews Ritual Chocolate

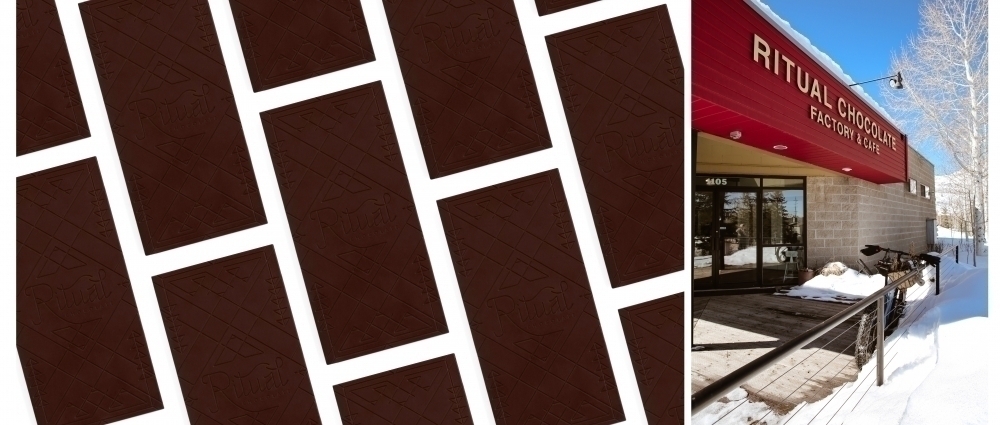

It’s time for another installment of For the Love of Making Chocolate. We were able to get in touch with Anna Davies from Ritual Chocolate, an artisan bean-to-bar small batch chocolate company located in Park City, UT. In our interview, we discovered how Ritual Chocolate uses European chocolate-making techniques to elevate the experience of savoring chocolate. We also get into their sustainability efforts. Everything in their process has been thought out in order to maximize the resources available to them. For example, their factory was designed with the natural heat produced by the sun in mind, so they can use this as a heat source of keeping their chocolate melted during production.

Read on to learn more about this mindful and unique chocolate company.

Can you discuss the history of Ritual Chocolate and how you got into the world of making chocolate?

In 2009 we began Ritual Chocolate as inspired creators, lovers of fine food, and the outdoors. As we explored good food and drinks, we noticed a lack of high quality chocolate. There was no clear product we could find that was truly transparent, educated people on chocolate making and really got people excited about the potential of chocolate as a fine food. After extensive research, we wanted to share what we had learned about chocolate history and it’s process from bean to bar as so few people really know how chocolate is made, where it comes from and who is involved in the process.

So we began making chocolate in our small studio apartment in Boulder, CO, using tiny machines we purchased, built and modified. We were so excited from the beginning to share what we had made and why it was so special. Fast forward 8 years, we have moved to Park City, UT which is a place that inspires us daily as makers and we continue to grow and make the best quality chocolate possible by adhering to many of the practices of great European chocolate makers before us, while incorporating modern methods.

Based on your mission statement and product line, it seems your goal is to really elevate the experience of enjoying chocolate. Can you talk a little about how the design of your products helps you achieve that?

We believe that chocolate is a fine food to be savored. We approached our bar and packaging design with this in mind. We have always thought our chocolate should be enjoyed as more of a tasting experience than a quick snack. We wanted the package opening and bar tasting to feel special for each customer, so with each step of the package opening we include information and design about us to connect with people, so they will slow down and really think about the chocolate they are about to eat.

Your company seems focused on protecting the natural resources that contribute to the chocolate-making industry, can you discuss your sustainability efforts?

We take our cacao sourcing seriously. With each farm or co-operative of farms we work with we truly believe in their practices that support heirloom genetics and sustainability for the farming community. We are in it for the long haul with these partners, as they often have to navigate price changes, difficult harvests, and other inconsistent buyers. For our cacao, we always make sure it is being grown organically, whether or not it is certified organic. At this point, about 80% of our cacao is actually certified organic, and the other 20% we know is grown organically. As for our sugar, we only use organic sugar (that’s an easy one). It’s subtle, but the way we designed our factory optimizes heat from the sun. We’ve installed all our grinding equipment, especially our conche, near or directly in front of our south facing windows, so especially in the winter, all the chocolate we want to keep melted is aided by the sun’s heat. Conversely, for the parts of our process that we like to keep either the chocolate or the beans cool, we’ve placed all those processes on the north side of our building, or at least out of the warmer south end of the building. A bit more on our location as well… we moved our factory up to 7,000 ft in the mountains where it is extremely cold for most of the year, and fairly cold at night in the summer. This alone saves us a lot of air conditioning costs and helps us save energy. At 7,000ft in Utah, it is also very dry—we practically have zero humidity. The negligible level of humidity means that we also don’t have to run dehumidfyers all day every day, which saves a lot of energy relative to other factories located in humid areas. As for packaging, our current package is recyclable and the inner pouch is not. However, as of very recently, we’ve already placed the order to replace all of our inner sleeves with 100% biodegradable packaging, which we expect to begin using by June 2019—and between the compostable inner sleeve and the recyclable paper outer package, our chocolate packaging will essentially be zero waste. Lastly, in our production process, our only waste product is cocoa shells, and this, we dispose of entirely as compost or donate to local gardeners. As we grow, we will continually strive to find ways to be less wasteful and more energy efficient. Our next goal is to go 100% solar, but we have to sell more chocolate first.

How are Micelli molds integral to your final product?

With every chocolate bar, the final reveal of the bar within the packaging is important to that final impression on our customers. We wanted to create a mold that was an extension of the rest of our brand while also keeping the integrity of the bar. Working with Micelli, they were able to create our mold design on paper and send samples of molds for us to test and make small adjustments as needed, so we could perfect our mold quickly.

Something else we love about the Micelli molds, is how well they hold up to repeated tempers with vibration and heavy tapping to create an even bar. We are hard on our molds with the tempering and washing and we consider the Micelli molds true work horses.

What is the inspiration behind your unique design?

Our inspiration comes first and foremost from having our chocolate factory in the Park City mountains. We chose Park City for our location as we feel so strongly about being in nature and having access to the outdoors. This is where we draw our inspiration from and what makes us feel whole.

When it came to our design, we wanted nature and mountain elements with a modern feel. Our color palette is pulled from the Utah scenery, such as the red rock and sage green. And as serious as we are about our chocolate making process and love of the mountains, we still wanted our design to feel fun and approachable for people, so we added some playful elements such as our animal icons and our “Best Enjoyed…” suggestions on the inside of the package such as “Best enjoyed at a mountain meadow picnic with raspberries and champagne” for our Ecuador 75% bar.

What products in your line are you most excited for a person new to your chocolate to try?

That’s a hard one as we love to share all our bars, but we love to start people new to craft chocolate with our Madagascar 75% bar. As the Akesson Estate beans are so bright and fruity it really shows people the flavor potential of dark chocolate when you are using exceptional quality beans with unique flavor.

For the Love of Making Chocolate,

Micelli